|

||

|

|

||

Solar System DesignUsing our 7200s.f. home installation, The largest in North America to date I am going to give you a run through in Solar System Design. This extremely well designed system affords the opportunity to discuss almost all important aspects of solar design and give working examples! |

|

|

|

The Envelope

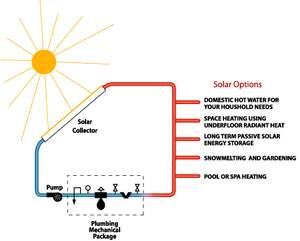

The first consideration with any solar design is the Envelope. The envelope has to hold as much of the sun's energy as possible when collected, and for as long as possible. This is the main reason we went with Radiantec, as they had a method to store passive solar energy for a long time. Because we live in New England, this was the most important feature, and the one we had to pay close attention to. Unlike the west coast that receives 300+ sunny days a year, here in New England we are lucky to receive 150 sunny days a year, so we must make the most of them. Below is a high level picture of a solar system with all the options available to you once you collect the sun's energy.  Next we will discuss all the components of the solar project and the significance of each step of the process.

First the Envelope, and its components;

Next we will discuss all the components of the solar project and the significance of each step of the process.

First the Envelope, and its components;

The Envelope:

|

|

|

Windows I started with the windows. I knew we wanted to install the lowest U-value, and the highest R-value we could find out there, and they had to be a type of window that would survive climate changes from -20F ~ 100+F, in addition very high winds upwards of 80mph, as well as driving rain, we are talking horizontal at times, The rate of heat loss is indicated in terms of the U-factor (U-value) of a window assembly. The lower the U-factor, the greater a window's resistance to heat flow and the better its insulating properties will be. The nationally recognized rating method by the National Fenestration Rating Council (NFRC) is for the whole window, including glazing, frame and spacers. Center-of-glass U-factor is also sometimes referenced, and describes the performance of the glazing alone without the effects of the frame. For most energy efficient windows, the whole window U-factor is higher than the center-of-glass U-factor. High-performance double-pane windows can have U-factors of 0.30 or lower, while triple-pane windows can achieve much lower U-factors. Low U-factors are most important in heating dominated climates, although they are also beneficial in cooling dominated climates. ENERGY STAR provides recommended U-factors for your climate. Nevertheless, because the windows in the Lodge had only been installed for 15 years, double pane construction, and all had failed, by leaking between the pains, and around the seal at the edges. The windows on the south side of the lodge were literally falling apart after only 10 years. So my search brought me to a Canadian manufacturer named "Loewen". The window was specified as triple pane, with 2 low-E layers with a very low U-factor,(0.12) and an R-factor of (8~9+) center of glass, all metal clad on the exterior, with fur wood construction, and best of all, a 20 year "Non Prorated" warrantee.

The difference between U-factor and R-value? While the U-factor is used to express the insulation value of windows, R-value is used for insulation in most other parts of the building envelope (walls, floors, roofs). To compare R-value and U-factor, divide 1 by the U-factor number, E.g.: a 0.25 U-factor equals a 1/0.25 = 4 R-value. One of the tests I made on the windows was to measure the indoor temperature of the center of glass vs the temperature of the wall directly next to the window. With an outdoor temperature of +10 F, and an indoor temperature of +68f, using a laser thermometer measuring the temperature of the wall at 68f, the center of glass on the Loewen window measured 64f, a difference of 4d at the center of the window. And as I move the laser beam closer to the edge of the glass I was reading an additional 2d cooler. "Not bad." Walls Because I had such a large area to work with I was able to create an inner wall within the standard 2x6 construction, I created a 2" offset with an internal 2x4 studded wall. This method gave me a 14.5" deep wall to insulate using Cellulous blown in insulation; I was able to create an R57 wall which worked very nicely in such a large structure, and still left us plenty of space with the added feature of nice deep window sills. Of course this is not always possible or required, but the most important element in the construction of the wall and its insulation integrity is to break the thermal transfer of the cold from the outside to the inside, and there are many ways to achieve this using other materials when space is an issue. One I used in other parts of the Lodge was adding 1" rigid foam board on the inside of the studs under the sheetrock. This does a nice job of breaking the thermal transfer of cold to the inside space. In areas where exposure was a problem I chose spray foam. By using 3" of foam on the exposed areas of the house we completely sealed the structure from wind and as a result, we made the structure very very stable in high wind situations. I found by using foam and sealing the walls to the sill plates and top plates the structure became bonded together and could withstand high winds, as well as seal out drafts completely. http://www.sprayfoamdirect.com is a really good source for materials and savings. The roof and the insulation. The roof is a typical Truss design with an energy efficient "Ultra-cool Englert" 24 gauge metal standing seam roof installed. (Roof Vendor: http://www.englertinc.com/) The benefits of a metal roof include the following but are not limited to;

Our Insulation Vendor: http://www.sprayfoamdirect.com I used blow in Cellulose, and did most of it myself to save some money. It wasn't hard but you need two people to do the job right. Foundation and Earth Box Insulation For any new foundation work, I designed in a product called I-C-F blocks. You may have seen them being installed because they are white in color, and go together like an erector set. ICF construction sandwiches a heavy, high-strength material (reinforced concrete) between two layers of a light, high-insulation one (foam). This combination creates a wall with an unusually good combination of desirable properties: air tight-ness, strength, sound attenuation, insulation, and mass. More foundation info: http://www.amvicsystem.com The product gives you an R50 foundation when the concrete is added, but the value is much more than that, because air cannot penetrate the system once it is completed. Once the foundation is completed we can begin to build our "Earth Box". The earth box is a system of its own. It needs to be 16" ~ 24" deep, Insulated at the bottom, and the perimeter with R10 material or better. The best application would be to use the 2" rigid foam board on the bottom, and on the perimeter. The reason I emphasize the perimeter is because we lose heat horizontally, so over insulating the perimeter is always a good thing, and never a waist of material. Once the Earth box insulating is completed, I recommend filling it in 50% full with the material you will be using for your earth box. Either flow fill, or sand. Either product is fine, the flow fill is a little more expensive, but creates a nice mass to store heat that seems to last longer, and dissipate a little more evenly than just using sand. Oh and one more fact that could justify using Flow fill is that you do not need to compact it once it's installed, so you need to do the math to see which material is right for you. This link will give you all the information you need to make a clear decision on I-C-F blocks, and flow fill. http://www.nnecpa.org/ Once the Earth box is 50% full it's time to install your Plumbing manifold and the pex tubing. ++IMG++ add earth box image(s) here It's a good idea to install the manifold in a location such as the back of a closet in a bedroom so it's out of the way, but you can still get to it. This is where you need to refer to your plans, and then start laying out your mesh in the Earth-box to attach the tubing to. This is important because you need to strap down the tubing to a specified spacing based on your specific design. Mine was a spacing of 12" using 7/8 pex tubing, and the length of tubing we used was 200' lengths. Once you have completed this process it's time to complete the filling process to the top of the Earth Box. After your pex tubing is installed according to your design, the next step is to pressure test each circuit. The plumbing manifolds I ordered from Radiantec came with pressure connections and gauges already attached. I simply had to fill the lines with air and check for leaks. As long as the lines hold pressure for at least 2 hours you should be ready to move on. Sometimes I like to let it hold overnight, but that's not necessary, 2 hours should be sufficient. I also recommend leaving the air in the system while your earth box is being filled. This helps give you the confidence that nothing bad is happening to your tubing while the work is being done during the filling process. The next step once your earth-box is completed is the slab tubing preparation, or what is called your domestic zone. The same principles as the work in your earth-box apply; only this zone will have hot water running through it instead of antifreeze. Also if the floor is concrete the spacing should be 16" on center instead of 12" on center, but this will also differ slightly based on the size of the tubing you are using for your specific design. Once your earth-box and domestic zones are completed, pressure tested, and the floor is poured and holding pressure, you can start to work on the plumbing between the earth boxes and the PMP "Pump Mechanical Package", as well as you're domestic heating connections from your zone pumps. At this point we need to talk about solar storage using passive storage tanks, and your back up heating system. Based on the size and complexity of your system will depend on the number of passive storage tanks you need to use. Keep in mind that my system is one of the largest residential solar heating system in all of North America, so your system will be much simpler to install. You will still need to make sure you have a plan for getting from point A to point B, meaning from your manifold boxes back to your PMP and mechanical room, and using basic plumbing practices will get this part of the job done right. One issue I ran into was feeding 2 earth-boxes with one 1" supply line, and bringing both E-Boxes back using one, 1" supply line. If there was one thing I would do differently is to use separate feed lines to the E-boxes, and still use the one common return line. Because of this installation path, I found it very difficult to purge air out of the system because I had the common feed to both E-boxes, and also to balance the pressure going to each zone was a little tricky. Both problems could be solved by using unique plumbing designs for each zone. Plumbing for the "Closed Circuit" and the Open/Domestic Circuit. The closed circuit is the connection between the actual Solar panels and the solar Hot water storage tanks, and the Earth Boxes. This circuit is isolated from the domestic Hot Water system, and is filled with Antifreeze. This loop could also include a garden, a pool, or a driveway heating system. These systems have many functions in the grand scheme of things to help the system work efficiently in all seasons. I will expand more on this subject later. Depending on how many solar arrays you have in your specific design, will determine how you have to divide up your arrays. Arrays should not be more than 8 panels in parallel, because in the summer when the system runs at its maximum temperature (220~300+d) the array will not expand so much that it will cause an overheating problem to the plumbing in the array. Now let's talk about the placement of the solar panels themselves. The panels have to be well secured to either a roof system, or a ground mount frame system. I prefer a ground mounted frame system as that will give you the most flexibility related to placement and access. If you have the space and the southern exposure, ground mounting is the way to go however, this is not always the case and a roof system will be more logical. Depending on your geographical location, you should try to face your panels so they are South, South West, but only a couple of degrees to the west if possible so you can maximize your exposure per day. What you are trying to achieve is at least 5 hours per day of quality Solar collection time during the winter season. This will give your system enough energy to create quality Hot water, and provide quality energy to your earth box to sustain comfortable temperatures in your home. The Open Circuit, sometimes called the Domestic Circuit is the tubing like in most hot water heating systems in homes is connected to your furnace and a water source. Each zone will have its own thermostat to control the pump or circulator circuit turning on and off to maintain the comfort level in each zone. The nice feature of an open direct circuit is that in the summer you get some cooling transfer as the return water always runs through your tubing every time you run the water, and always keeps the water in the tubing fresh. Unlike in conventional heating systems the water stagnates during the summer months and turns black.

|

||

|

Home | About | My System | Solar System Design | Cost Savings | Contact Us |

||